|

- Our enterprise has vast experience in developing multi-spindle drilling heads and high-speed grinding heads for the automotive industry.

- We have the experience in developing automatic milling machines designed for grooving fixed blades in electric shavers, also automatic presses for oil refining industry.

- We develop semi-automatic machines for manufacturing blister packaging for food products and also tooling for packaging machines of Italian manufacturer.

- Our enterprise developed and manufactured liquid bitumen mixers of various types and sizes used for manufacturing of roofing materials.

- Various types of cassettes, trolleys, laboratory furniture were developed for use in pharmaceutical industry

- Using such software packages as Catia V5, SolidWorks or Pro-Engineer, we are able to develop customer tailored equipment of any degree of complexity to be used in other industries.

Description of Photographs

1. Reverse Osmosis High Purity Water Unit

Tap water is supplied to the unit inlet. Water is treated by a set of filters and then supplied to the inlet of the Reverse Osmosis Unit. After the Reverse Osmosis Unit the water is fed to ion-exchange filters, and further it is passed through sterilizing cartridge filter. Water has no more than 10mg/litre of a solid residue at the unit outlet. Unit capacity is 100 litres per hour.

2. Semi-Automatic Flask Filling Machine

Semi-Automatic Machine is designed for filling flasks with high viscosity preparations. It is a cassette type unit.

A cassette with an empty flasks is placed on a semi-automatic machine feed table. All flasks in the cassette are filled with the preset amount of preparation in the automatic mode. A cassette is removed from the feed table and the feed table returns to its starting position; the whole process repeats again. Characteristic feature of the unit is absence of moving parts on the path of medication, due to its high viscosity. Dosing is carried out with the help of pneumatic automation.

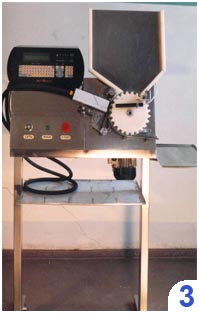

3. Marking Machine

Automatic Marking Machine is designed for applying scripts on the ampoules and flasks. Marking is carried out by bubble-jet printing technology. Ampoules drum fed. Capacity: 12 000 ampoules/hour.

4. Medication Sterile Filtration Unit

The unit is designed for filtration of medications immediately before filling into the ampoules or flasks. The medication is supplied to the unit inlet from the reactor by extrusion with inert gas. The extrusion pressure forces the medication through the first two filters and into the intermediate vessel. Peristaltic pump flushes the medication from the intermediate vessel through the sterilizing filter and into the packaging; the excess returns to the intermediate vessel.

Unit Capacity – 70 litres / hour

5. Medication Sterile Filtration Unit

This unit varies from the above described, in that the supply of the medication from the reactor is carried out by the peristaltic pump of the unit, which means, in this case, there is no need to supply pressure to the reactor. As for the rest the units are identical.

|

|

|

|

|